The use of Low Temperature Soldering (LTS) is gaining considerable interest in our industry to reduce cost, prevent component/substrate damage plus improving assembly reliability. It’s different but that does not mean it cannot be introduced on your site with existing equipment or with our support at your contractor

Generally speaking, lead-free solders used in assembly reflow above 220C, low temperature solders reflow well below 180C which provided benefits. There are some organization like iNEMI predicting a large growth in low temperature materials in the next two to three years for multistep soldering growing from 8% paste volume in 2020 to over by 15% in 2024

Generally speaking, lead-free solders used in assembly reflow above 220C, low temperature solders reflow well below 180C which provided benefits. There are some organization like iNEMI predicting a large growth in low temperature materials in the next two to three years for multistep soldering growing from 8% paste volume in 2020 to over by 15% in 2024

Watch some of our Low Temperature training Videos Online

Many companies have been using tin/bismuth and tin/silver/bimuth alloys for some years reducing cost on PCBs and energy. Other companies have been using tin/indium for rework of lead-free area array packages with good success. There are savings to be made even if the cost of some solder alloy is more expensive provided you consider the total cost of manufacture

We produced the first book, video and interactive training on Pin in Hole Intrusive Reflow (PIHR), so we believe we are in a very good position to help engineers achieve high yields with low temperature materials with through hole parts

We produced the first book, video and interactive training on Pin in Hole Intrusive Reflow (PIHR), so we believe we are in a very good position to help engineers achieve high yields with low temperature materials with through hole parts

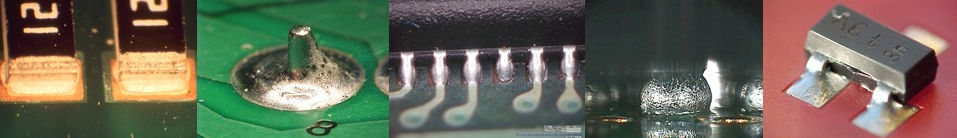

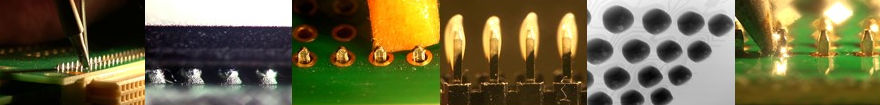

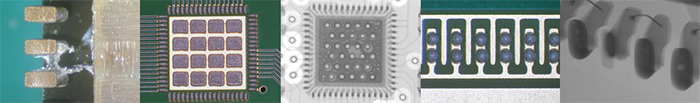

As a special part of our training options we are providing a FREE package of inspection posters for onsite reference plus access to a growing library of LTS photography and videos that can be used onsite for further in-house education and reference. Over the years we have worked with Indium, Alpha Metals, Multicore and Nihon Superior and hope to work with many others suppliers in the coming months with the practical implementation of Low Temperature Soldering Solutions for customers worldwide

View some of our low temperature soldering Images Online

We offer practical hands onsite workshops using LTS materials with your current suppliers. Alternatively we can offer online sessions for you and your team, the content of each can be modified from the example below

We offer practical hands onsite workshops using LTS materials with your current suppliers. Alternatively we can offer online sessions for you and your team, the content of each can be modified from the example below

What Your Team Will Learn:

Why use low temperature solder

Benefit over lead-free SAC alloys

Material availability

Solder paste evaluations

Solder paste printing

Use of joint support materials

PCB and component solderability

Reflow soldering and rework results

Use in selective & wave soldering

Robotic through hole soldering

Reliability with mixed alloys

Inspection results for paste and joints

Defect types and joint failure

Surface mount and area array rework

Manual Soldering and de-soldering

How Your Team Will Benefit:

The hands on workshop can illustrates the practical use of LT materials in reflow, selective and rework processes so the content should benefit Process and Quality Engineers. As inspection and defects are covered it will also be ideal for Product Operators, Supervisors and Line Managers tasked with its implementation. Using new alloys the long term reliability is crucial so design engineers will benefit with being involved