We have created two new online webinars for our worldwide customers. All you need to do is book a webinar online through our website for your engineering team. Your book and pay once for your team on multiple sites. You can then invite any of your company engineers at different sites to join in from their factory or home office. Its that simple to spread information world wide and minimum cost

We have created two new online webinars for our worldwide customers. All you need to do is book a webinar online through our website for your engineering team. Your book and pay once for your team on multiple sites. You can then invite any of your company engineers at different sites to join in from their factory or home office. Its that simple to spread information world wide and minimum cost

This is one of our most recent services to industry and you are only limited to 100 people attending. If 100 members of your global team participate that works out less than £5 pounds, $6 dollars or 6 Euro per engineer

Tombstoning Components During Reflow – Causes & Cures

Solder Preform World – Not New Technology but Interesting Option  Solder Preform World – Not New Technology but Interesting Option

Solder Preform World – Not New Technology but Interesting Option

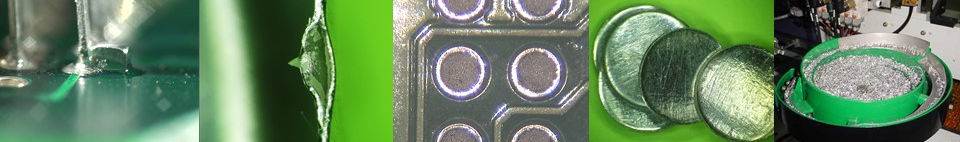

Solder preforms are normally solid solder shapes specifically designed to make one or multiple solder joints in one reflow operation. Solder preforms can be coated, flux laminated between layers of different alloy or simply compressed cored solder wire. In the past some assembly operations have simply employed cored wire wrapped around a screwdriver cut to form rings

Preforms provide a defined volume of solder to form a reliable joint with the assembly process automated if volumes require. Through hole paste reflow can benefit using solder bricks to increase joint volume and decrease flux residues. Some placement machine suppliers offer cut and form feeders, so solder wire is used, reducing the cost of precision preforms

Back in the day the presenter used preforms with vapour phase for feed through capacitors, wire wrap back planes, heat shields and cable forms. Welcome to the interesting world of solder preforms

Our first webinar includes:

Soldering Applications

Solder alloys

Preform types

Fluxing options

Preform packaging

Soldering and temperature profiling

Reducing void formation

Traditional soldering, wire connections, die mounting & more

Inspection and process defects

Presented by Bob Willis

The webinar will run between 60-90min with a question and answer session. If you have a specific problem or failure, then please send your photos and examples in advance of the webinar. The webinars are limited to 100 delegates/companies. A copy of each of the slides presented will be provided after the webinar in pdf

In preparation for the event and to ensure you are equipped to get the maximum benefit from our event, please read this simple Webinar Guideline

Tombstoning Components during Reflow – Causes & Cures

Tombstoning Components during Reflow – Causes & Cures

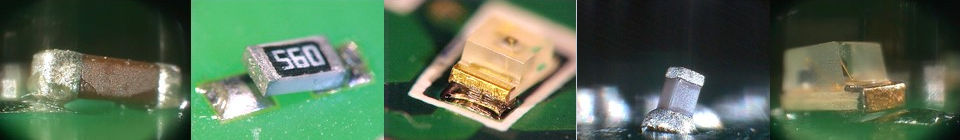

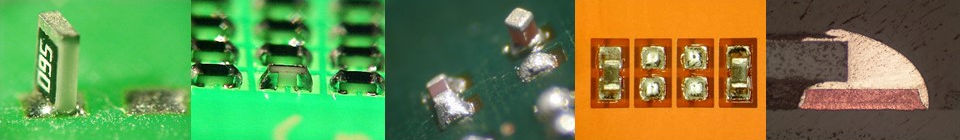

Since the introduction of surface mount technology (SMT) components to the industry in 1980’s engineers have experience unplanned lifting of parts. These defects are referred to as tomstoning, drawbridge, Manhattan skyline, crocodiles, or billboards the list is endless. Lifting of parts became common during the transition of manufacturing from ceramic hybrids to organic laminate PCB’s

Tombstoning can be seen directly after reflowing side one or two. The issue is experienced in convection, nitrogen, vapor phase and laser soldering. Some say it has increased with component becoming smaller moving from 0402 to 01005 chips. Through careful review and modification of process parameters some defects can be reduced, but not all

Lifting of components may not be detected on existing older AOI systems, but new advanced vision should be able to detect very subtle lifting leading to opens. With Bobs many video experiments delegates will be able to watch this lifting taking place and be able to see some of the causes demonstrated live

Topics covered:

Design rules for passive components

Pad sizes – solder mask – surface finish

Test boards and process trials

Klein Wassink/Philips calculations

Solder paste type & volume control

Reflow soldering

Convection/nitrogen, vapor phase & laser soldering

Inspection & defect analysis

Simple rework of lifted parts

Presented by Bob Willis